- Ronda Narcís Monturiol, 29, 08349, Barcelona, Spain

- Mon - Thu: 8:15 - 18:30 / Fri: 8:15 - 14:00

- Fri: 8:15 - 14:00

FIND THE PACKAGING YOU ARE LOOKING FOR

GET OUR EXPERTS’ ADVICE

In Rovi Packaging we have a factory of BIO bags that allows us to meet the expectations and orders of large brands and small businesses that seek to differentiate themselves through the packaging of their products, offering a more sustainable solution with the environment.

Our production process has a very important part in Spain, which allows us to have greater flexibility when it comes to meeting minimum quantities and delivery times.

The consumer is increasingly demanding, choosing materials that have a lower environmental impact, which is why at Rovi Packaging we have positioned ourselves at the forefront of the packaging sector by adapting our production system to these new materials.

Compostable, water-soluble, recycled, recyclable and reusable materials, among many others, are our commitment.

We help our clients in the ecological transition of their packaging, moving from conventional plastic to more BIO options such as paper or other biodegradable solutions.

The vast majority of our customers call us or fill out our contact form and are interested in the BIO bags that best suit the needs of their packaging project. Once we have your details, our sales department will contact you within 24 hours.

On the first call we ask a lot of questions. It's important that we know your needs and that we can capture all the necessary points and aspects that your BIO bags packaging project is going to need.

We make a study of the cost of the material and the delivery times and we translate them into a closed budget that we send you within a maximum of 72 hours since you have provided us with all the details of your BIO bag packaging project

Once you approve the budget, we get down to business and focus on getting our BIO bag factory up and running. We keep you informed at all times of the status of your order and the estimated final delivery date.

Once the product has been manufactured, our quality control department carries out the corresponding analyses to verify that the BIO bags comply with Rovi Packaging standards and if everything is correct we deliver the order.

As a BIO bags factory, there are different materials that have to be taken into account. On the one hand there are recycled plastics, which follow a production process very similar to conventional plastic bags. The same happens with the compostable plastic bags, which have a resistance similar to the conventional plastic.

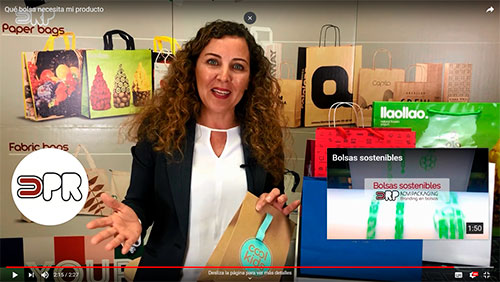

We also have the category of BIO paper products, such as Kraft bags, as you can see in the attached video, we have customers of leading brands in this regard.

Finally, we must also consider cloth bags, which can be reused many times. Cotton, jute and juco are examples of fabric materials that are being used more and more because of their ability to be reused and therefore reduce waste.

In short, at Rovi Packaging we are aware of the importance of climate change, which is why we are committed to manufacturing bags made of recycled, compostable, biodegradable, water-soluble material, among many other materials.

We are the bag manufacturer for big brands like Lindt. In this case we make all the packaging, both luxury bags and recyclable and environmentally friendly paper envelopes. We are the packaging partner that responds to the changing demands of our customers.

For the conception of the DAMM product we are dedicated to translate the simplicity and elegance of the product in a high range bag of rope handle. The intention was to transmit high quality, differentiation and the values of the brand Inédit through the packaging.

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.